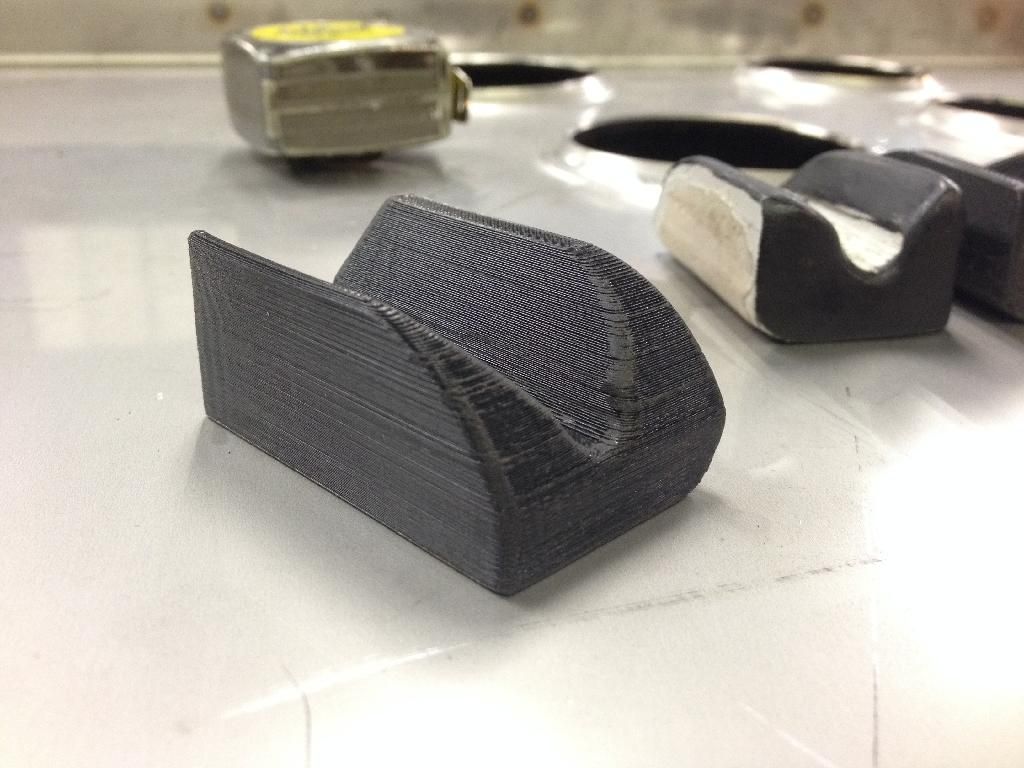

Long story short, I met a guy through work that has a 3d printer. I was instantly intrigued and expressed and intrest in having a rest made for my BE1, since I can't get an Esper rest for it. So today I brought the guy my bow, showed him my epoxy rest, and asked him if he could duplicate something similar.

We popped the epoxy rest off my bow, he's going to print me one up tonight as a favor. If it works out, I could have a batch printed up, however I'd have to make a dozen or 2 to keep the cost per rest reasonable. This would include the materials, his programming and machine run time. Is there any intrest in a group buy "epoxy" style rest for the BE1?

We popped the epoxy rest off my bow, he's going to print me one up tonight as a favor. If it works out, I could have a batch printed up, however I'd have to make a dozen or 2 to keep the cost per rest reasonable. This would include the materials, his programming and machine run time. Is there any intrest in a group buy "epoxy" style rest for the BE1?