Hello I recently bought a bare hull 1860 riveted polar kraft. I just got it in the garage finally. Im a little stumped on how I can strengthen the flex of the whole boat.

Here's the problem, when I pick up the front left side of the boat, it lifts 2.5" before the back left side of the boat will start lifting up. If that makes sense. I feel it is too flexible and could cause cracks in the future.

I only have 1800 into it so I don't mind putting a little bit of money into it but would like to keep it under a grand.

My thought was to make side benches around both sides that could work as a walk around too. Also I'm going to put a full floor in it. The floor supports are shaped in a small v so I was thinking about running 2x2x1/4 angle on the floor supports and putting a brace in the center where there'd be about a 2" gap. Gluing and riveting the floor down with structural glue and structural rivets.

The front deck is crap. But I don't know how to take it out and how to tie into the sides for a heavier duty front deck. Also if you go a foot behind the front deck the gunnels have a 1/4" flex. It has 24" sides and I've seen boats with higher supports up the sides. I assume that is to take the flex out of the gunnels.

My concern is that if I build a deck and lay it on the gunnels it will possibly stress Crack the sides. Let me know what you guys think besides "scrap it" or "buy new"

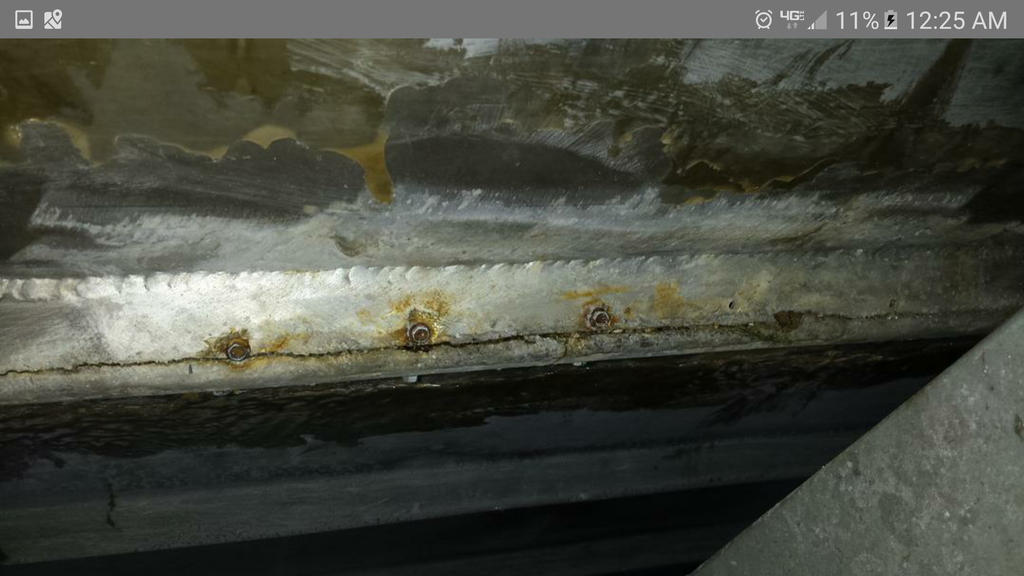

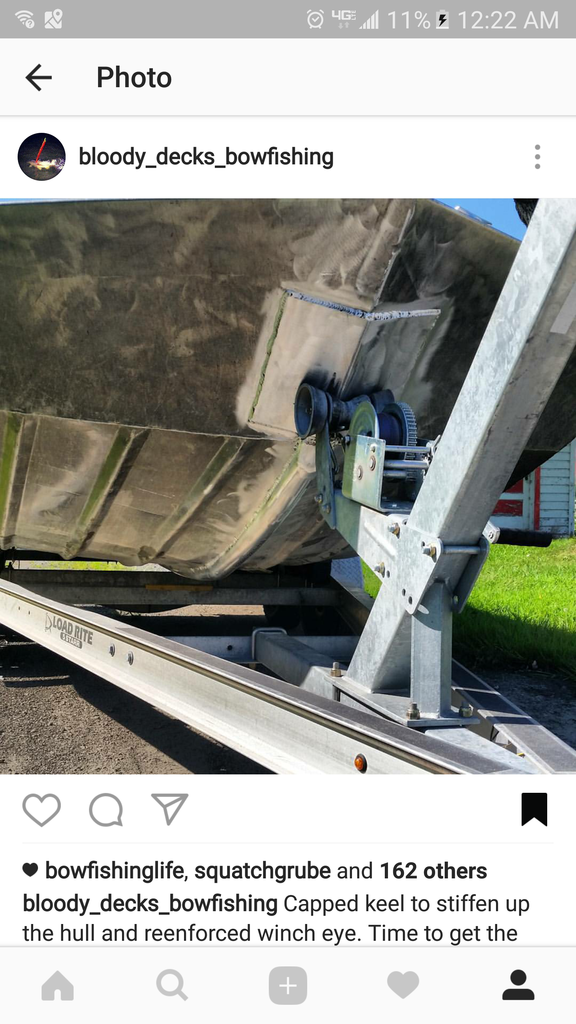

Thanks! Here's the pics

Here's the problem, when I pick up the front left side of the boat, it lifts 2.5" before the back left side of the boat will start lifting up. If that makes sense. I feel it is too flexible and could cause cracks in the future.

I only have 1800 into it so I don't mind putting a little bit of money into it but would like to keep it under a grand.

My thought was to make side benches around both sides that could work as a walk around too. Also I'm going to put a full floor in it. The floor supports are shaped in a small v so I was thinking about running 2x2x1/4 angle on the floor supports and putting a brace in the center where there'd be about a 2" gap. Gluing and riveting the floor down with structural glue and structural rivets.

The front deck is crap. But I don't know how to take it out and how to tie into the sides for a heavier duty front deck. Also if you go a foot behind the front deck the gunnels have a 1/4" flex. It has 24" sides and I've seen boats with higher supports up the sides. I assume that is to take the flex out of the gunnels.

My concern is that if I build a deck and lay it on the gunnels it will possibly stress Crack the sides. Let me know what you guys think besides "scrap it" or "buy new"

Thanks! Here's the pics